About cauldron

Right workholding can decrease the possibility for error and make sure that parts are machined to the proper specifications. Osborn shared a number of criteria when arranging a workholding technique:

When knifing, the urethane can have the inclination to pull in to the Resource. This displacement of material will induce a “dish†around the completed stop with the section. The thinner the Device, the much less the pulling impact on the Slice edge.

net. I understand that I am able to withdraw my consent at at any time. Be sure to seek advice from our Phrases of Use and Privacy Plan or Call Us for more facts. I agree to acquire these communications from SourceForge.Internet through the signifies indicated previously mentioned. I understand that I am able to withdraw my consent at whenever. You should confer with our Conditions of Use and Privateness Plan or Contact Us For additional specifics. JavaScript is needed for this kind.

machining Options

When carrying out any machining or other secondary functions on urethane, we advocate that each one suitable security gear along with private protecting gadgets be used constantly.

The natural way, it struck me as odd that the celebration presenting to obtain my corporation was on a single hand effusively praising what Andy and I experienced designed, and on one other invalidating its well worth. My incredulity finally morphed into discontent given that the negotiations slid even more and additional into oblivion.

A cauldron is a big pot utilised around an open fireplace. Chances are you'll picture the witches in Shakespeare's Macbeth hovering over a cauldron of "Eye of newt and toe of frog, Wool of bat and tongue of Pet dog" — yum!

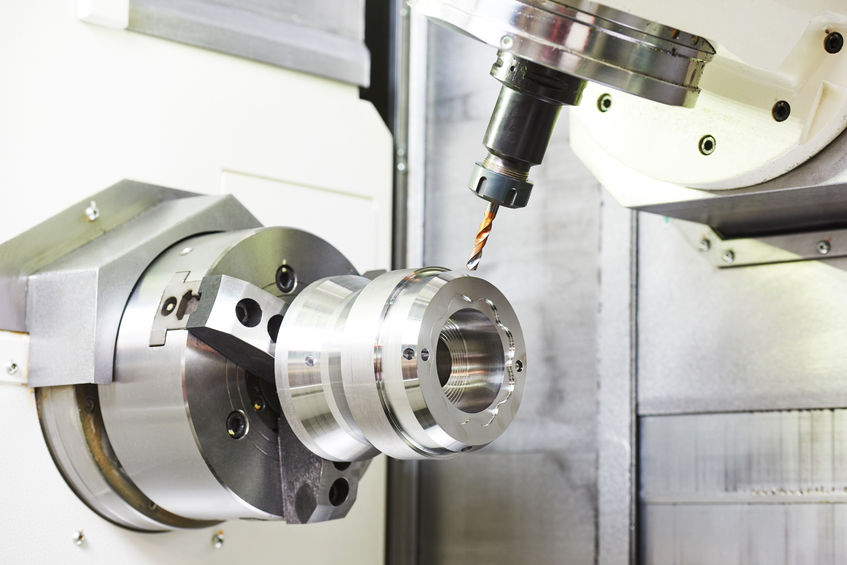

A drill can be used to eliminate metal in The form of the cylindrical gap. Other applications Which may be useful for various sorts of metal removal are milling devices, saws, and grinding devices. Lots of of such identical strategies are Employed in woodworking.

With all your prototypes we can easily converse much better and more quickly with our purchasers and provide them with a glance of how the product will look and feel like.Ing. Marc E.J. Van Strydonck Industrial designer

Getting My machining To Work

The machining Component of the procedure is handled within our area warehouse, then we ship the products to acquire their last step toward completion.

At some point, devices will be part of them within the assault…nonetheless, they indiscriminately assault both you and also the thugs. Use this to your advantage If you're able to.

By some means we managed to beg and borrow just enough content material from sympathetic and caldeiraria hungry freelancers — several of whom experienced previously recognized by themselves in sports activities media, Many others who just preferred the chance to have their get the job done found over a nationwide amount.

A firm linked to the business enterprise of machining generally would make parts for cars, health-related devices, air craft, or other equipment away from aluminum or metal.

A Secret Weapon For cauldron

three to five levels is everything will likely be required. See figure 2. The proper Instrument, feed, and speed allow the chip to exit the Reduce with minor resistance and warmth Make up. Parting yields a very good area complete and is particularly a helpful variation for dealing with particular urethane parts.